Metal Fabrication vs. Machining: Choosing the Right Manufacturing Process

You might wonder, "What's the big deal between metal fabrication and machining?"

Choosing between these methods can make or break your metal works project, influencing cost, quality, and other factors.

To fully understand how machining and metal fabrication interact, you must understand how they differ.

Allow us to walk you through metal fabrication and machining, highlighting their benefits and drawbacks.

So, if you work in manufacturing or are simply interested in how things are manufactured, keep reading because we'll get into the ins and outs of metal fabrication and machining.

Metal Fabrication

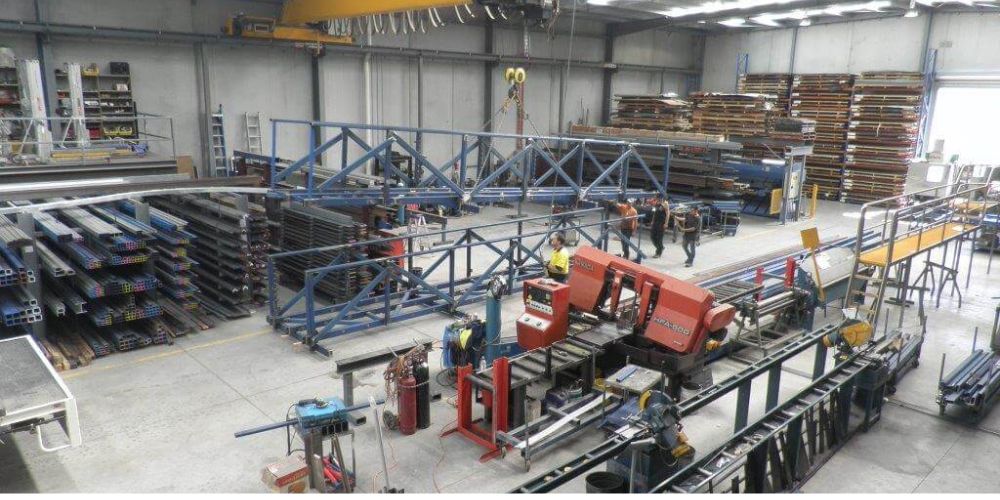

A manufacturing process known as metal fabrication entails assembling multiple machine-made components to create finished parts or products. It is a flexible method that is essential in many different sectors.

Let's explore what machine manufacturing comprises in more detail:

What is Metal Fabrication?

Definition and Explanation

We heard this question (and are continuously being asked) by different people, from acquaintances to clients, almost every time.

What does metal fabrication really mean?

Well, making parts or products out of machine-made components is known as metal fabrication. It uses various methods, including cutting, bending, welding, and assembling. This strategy combines parts made through various manufacturing processes or prefabricated components to generate a finished product.

Commonly Used Materials

In terms of materials, metal fabrication is highly adaptable. It may be used on various materials, including copper, aluminium, and steel. Plastics and composite materials are very often used in the construction of machines. The need for strength, corrosion resistance, and affordability influences material selection.

Advantages of Metal Fabrication

- Cost-Effective Production: Metal fabrication is renowned for being economical, particularly in high-volume manufacturing. Process automation and adopting standardized parts can result in considerable cost reductions.

- Complex Shapes and Sizes: The fabrication of complicated and sophisticated forms and sizes that could be difficult to produce using conventional techniques is now possible thanks to this technique. It's perfect for designs that need to be precise and distinctive.

- Mass Production Capabilities: In mass manufacturing, metal fabrication is excellent. It can reliably create high numbers of identical components or goods with little fluctuation, guaranteeing consistency and quality.

Limitations of Metal Fabrication

- Material Constraints: Although metal fabrication is flexible, not all materials will work with it. The characteristics of some materials, such as their high hardness or brittleness, may make them challenging to deal with.

- Tolerance and Precision: Although metal fabrication can attain great levels of accuracy, it cannot be as precise as possible with advanced machining techniques like CNC. Tight tolerances may constrain some applications.

Industries and Applications

- Automotive: In the automobile sector, metal fabrication is widely employed to produce car parts such as frames, chassis, and body panels.

- Aerospace: Metal fabrication is used to build aircraft parts, such as wing components and landing gear, in the aerospace industry, where accuracy and dependability are crucial.

- Electronics: To create the casings, enclosures, and structural elements of electronic devices, metal fabrication is essential in the electronics manufacturing process.

Machining

Let's get our hands dirty and explore the realm of machining, the skill of precisely removing material to create parts and components. I'm here to offer everything from what precisely includes machining to where it excels.

Definition and Explanation:

Okay, so what exactly is machining? Imagine doing something similar to carving a sculpture out of wood, except instead of using wood. You're using ceramic, plastic, or even metal. The trick ingredient? When shaping your workpiece, use sharp tools like cutters and drills to chip away pieces of material. Precision and having the last say in how your item ends are key.

Common Machining Techniques:

Machining includes numerous typical procedures:

- Turning: Involves rotating the workpiece while a cutting tool removes material to create cylindrical shapes.

- Milling: Utilizes a rotating cutter to remove material from a stationary workpiece, producing various shapes, slots, and contours.

- Drilling: Creates holes in the workpiece using a rotating drill bit.

Grinding: Achieves high precision and surface finish by abrasively removing material using grinding wheels. - Electrical Discharge Machining (EDM): Utilizes electrical discharges to erode material for intricate shapes and hard materials.

Advantages of Machining

- High Accuracy and Precision: Machining is your best option if your project requires absolute precision. It ensures every cut and contour is perfect, like the surgeon of the industrial world.

- Versatility: Machining uses various materials, including composites, metals, and polymers. It is a handy option for many sectors since it can handle a buffet of materials.

- Wide Range of Materials: Working with materials as soft as butter or as durable as titanium is no problem for machining. Like a skilled chef, it adjusts its methods to fit the ingredients.

Limitations of Machining

- Complex Parts are More Expensive: Here's the thing: machining requires meticulousness. It may get expensive when you have elaborate, sophisticated pieces with curves, edges, and hidden corners since it takes time and skill to get everything right.

- Additional Production Time: Precision takes time. Machining might not be your express lane if you're in a hurry. Manufacturing is akin to a slow-cooked meal where every aspect is carefully considered.

Industries and Applications

- Precision Engineering: Machining has your back whether you require gears, bearings, or anything else where accuracy is key.

- Medical Devices: Consider implants, surgical tools, or the tiny parts that keep medical equipment running well. They must be precise, and machining meets that need.

- Tool and Die Making: This is the point at which moulds, dies, and tools are created. They're frequently complex, and machining makes sure they're excellent.

Factors to Consider When Choosing Between Metal Fabrication and Machining

Complexity of the Part

Metal fabrication works effectively for basic designs since it can produce straightforward forms and pieces without challenging cutting procedures. But, if you have tricky shapes, need things to be super exact, or want lots of details, machining is a smarter pick because it can deal with tough shapes carefully.

Material Selection

Metal fabrication is versatile but may have limitations with certain materials. Machining is the go-to choice for working with various materials, from soft plastics to ultra-hard metals.

Material testing

Metal fabrication is versatile but may have limitations with certain materials. Machining is the go-to choice for working with various materials, from soft plastics to ultra-hard metals.

Tolerance and Precision Requirements

Metal fabrication can attain acceptable tolerances but may fall short of machining accuracy. Machining is the ideal option for tasks needing extremely tight tolerances and the greatest levels of precision.

Production Volume

Metal fabrication is cost-effective for high-volume production due to its ability to automate processes and use standardized components. Machining is a more practical choice for smaller production runs or one-off prototypes, especially if precision is important.

Cost Considerations

Metal fabrication is cost-effective for larger production runs due to economies of scale. Machining offers high precision but can be expensive, especially for complex parts requiring multiple tool changes and setups.

Lead Time and Production Speed

Metal fabrication is faster than machining, making it a good choice for those who need parts quickly. However, machining offers greater precision, albeit with a longer production time. Consider the trade-off between speed and precision when choosing between the two methods.

Environmental Impact

Metal fabrication is usually more eco-friendly than machining because it produces less waste material and uses energy-efficient production methods. However, sustainable machining practices are being developed to improve its environmental impact.

FREQUENTLY ASKED QUESTIONS

Conclusion

So there you have it! It might sound technical and confusing, but choosing between metal fabrication and machining boils down to finding the right tool for your job.

Don't let the jargon overwhelm you. Consider your project's complexity, materials, precision needs, budget, and timeline. With these in mind, you can confidently choose the method that suits your needs.

And remember, technology never stands still. There are always exciting innovations around the corner that can make your manufacturing journey smoother and more sustainable.

So, these are your trusty tools, whether you're all in on metal fabrication, fully embracing machining, or mixing and matching.

And remember, if still in doubt, expert metal fabricators (just like us!) are only one call away!