Metal Fabrication Tools Of The Trade

Steel fabrication is a physically demanding task. It requires expertise and precision, a strong understanding of physics and chemistry, and the precise implementation of some highly complex machinery. Although working with metal is a distinct art in and of itself. Some researchers have spent several years experimenting and studying what works best. Metalworking, like any other handyman craft, necessitates the use of the proper equipment. You're out of luck if you don't have them.

There are numerous uses for fabricated sheet metal, as well as multiple tools that are used to establish its functionality during various metal fabrication processes such as shearing, shaping, blanking, and punching. These are undoubtedly complex methods, and the fabricators who carry them out must be professional and experienced in their trade. Furthermore, they must have a wide range of high-quality equipment in the shed or their storage.

Here are the ten most popular tools of the trade for steel fabrication, providing a quick glimpse into the daily life of a fabricator.

10 Most Important Tools For Metal Fabrication

The list could go on and on, but we know you're interested in learning about the best metalworking equipment. We've compiled a list of the 10 most essential tools you require for metal fabrication.

Angle Grinder

This handheld power tool is used for cutting, grinding, and polishing various types of metal, which fab staff do frequently.

This tool can be used on a variety of metals, and with a variety of sizes available, you can find the ideal one for your application. Make sure you buy a long-lasting angle grinder.

Guillotine

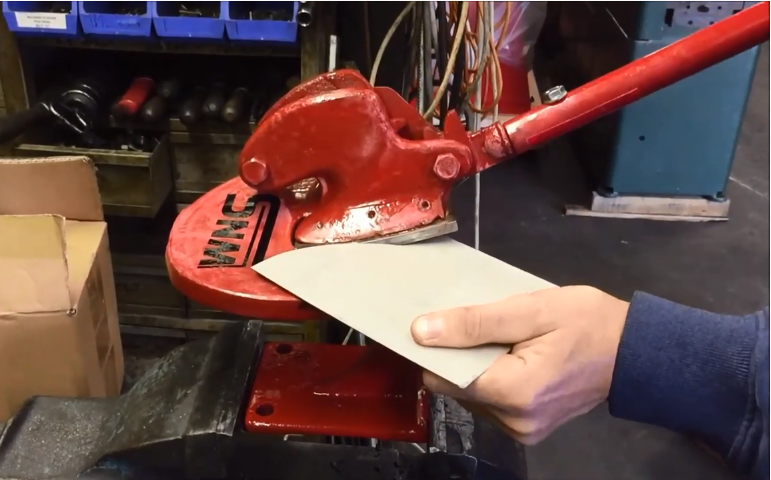

The guillotine has a complex past dating back to the Middle Ages, with precursors dating much further back. However, the style used by steel fabricators differs from what you would expect. The guillotine, also known as a ‘cropper' or ‘punch and shears,' is mechanically or hydraulically driven and is used to cut plates ready for fabrication.

It works by clamping the steel with a ram and then cutting it with a moving shear. Steel has an excellent ‘shearability ranking' and takes much less energy to cut than other metals.

Metal Cutting Saws

Circular saws, chop saws, cold saws, and band saws are all types of metal cutting saws. Band saws are much more reliable and stable than manual, handheld saws, making them the preferred tool.

A metal bandsaw is a saw with sharp blades and a row of sharp teeth stretched between two or more wheels. A good metalworking bandsaw is a must-have for anyone who deals with metal on a regular basis.

Bandsaws are flexible and ideal for beginning woodworkers. Bandsaws are available in a range of sizes and are widely used to aid in the cutting of curves and irregular shapes. You can quickly swap blades, giving you the ability to work with materials other than metal, such as wood.

Bending Tools

Sheet metal bending, as the name implies, is a mechanism in which the metal is bent while maintaining its volume constant. For this reason, various types of equipment and tools are used. The following are some of the most important tools and equipment used in the sheet metal bending process:

Bench Top Budget Brakes

This is a wide bench with a fixed lower beam and a variable upper beam. When bending aluminum, the upper beam of the benchtop sheet metal brake is used to build a radius.

Bracket Makers

This is just another piece of sheet metal bending equipment. The bracket maker equipment will create brackets of different shapes and sizes. This equipment's 90° and radius tools are very useful in bracket forming.

Nibbler

A metal nibbler is a tool that is used to cut sheet metal. The primary feature of the tool is to cut the sheet metal with minimal distortion. It serves as both a punch and a die. It travels in a straight line against a fixed die, removing small bits of metal and leaving a 6mm wide "kerf." They are usually propelled by compressed air. There are also electrical models available.

Nibblers would be ideal for cutting any narrow channels or cutouts on any home improvement project. They are also suitable for cutting corrugated sheet metal and perform nearly perfectly. The most common complaint from DIYers about metal nibblers is the amount of waste material they produce during the cutting process.

Cleco fasteners

Cleco fasteners are a form of temporary fastener that is used to hold sheets of material or other pieces together until they are permanently joined, such as frames or stiffeners. Consider it a more powerful clothespin.

They are typically used in the production and repair of aluminum-skinned aircraft to temporarily fasten sheets of material together or to keep parts such as stiffeners, frames, and so on together until they are firmly joined.

Beam Lines

Steel parts are drilled and notch using beam drill lines. They are highly complex pieces of machinery that offer much quicker drilling solutions than manual methods. They frequently use computer technology to accurately drill and notch holes in steel beams.

Beam lines allow for grinding, sawing, punching, shearing, coping, and fabrication of nearly all structural steel profiles (H, I, channels, angles, flats, rectangular and square tubes) and welded profiles.

Deburring and Bevelling Tools

Bevel mills, grinders, sanders, and other lightweight but durable deburring and bevelling equipment are available. With powerful motors and vibration-free running, you can achieve consistently high-quality performance.

Deburring tools smooth parting lines, jagged edges, and protuberances on the surface of an item produced during machining or casting operations. Beveling, on the other hand, is a method that is used to prepare metal for a welded seam by cutting an angle on the edge of the metal.

Throatless Shear

These are used to make straight and curved cuts in metal. The throatless shear is named for the fact that the metal can be easily pushed around the cutting blade (there is no metal throat that must be fed), offering several different geometric forms for cutting that are possible with it.

This metal shear cutter makes accurate and effortless cuts along straight and curved lines with a clean and straight edge or in the round or in other non-traditional shapes without stretching or wobbling.

Stretchers

Another process in which the geometry of sheet metal is altered by applying force is sheet metal forming. This force is sufficient to bend the material plastically by stressing the metal beyond its yield power. Material is not extracted from the metal during this process.

One of the most widely used stretchers is the shrinker stretcher. The shrinker stretcher tool is used to shape sheet metal without the use of heat, cutting, or welding. This method can be used to build smooth radius curves. The method is primarily used for creating inside curves and is accomplished by shrinking the metal on one hand.

Safety Measures To Take During Metal Fabrication

When dealing with metal fabrication, it is important to consider safety. A healthy working environment will reduce occupational accidents and save the organization money. Many accidents in a metal fabrication shop are the product of carelessness. Injuries can also occur while handling materials incorrectly, resulting in musculoskeletal disorders. So let's find out the tips for having a safe working environment.

Proper Education

This is an essential step in any metal fabrication project. Personnel should receive thorough instruction on the machinery, workplace hazards, and working conditions. In addition, workers should be educated on correct safety procedures in order to avoid injuries.

Use of Proper Tools

Fabricators must ensure that proper tool use is followed after receiving the requisite training. They can read all of the instructions and learn how to use each method properly. Before using the tool, it should be thoroughly tested for flaws and losses. Fabricators should also be aware of whether or not big machines are running properly.

Clothing

In the fab store, all employees should dress appropriately. Loose clothes can get entangled in heavy machinery and cause injury, so anything that can get stuck, such as hair or jewellery, should be tied back or removed.

Regular Inspections And Maintenance

Regular checks and maintenance procedures must be carried out to fix or instal any defective machinery and other equipment to ensure that the workplace is safe 24 hours a day, seven days a week.

Safety Gear

When handling any machinery or materials, protective clothing and equipment, such as hard hats, goggles, gloves, earplugs, and safety shoes, should always be given. Because of the high risk of being entangled in the machinery, no jewellery or loose clothes should ever be worn. This safety equipment will ensure that the workers are still operating in a secure atmosphere and are not exposed to any occupational hazards.

Without a doubt, safety and productivity are closely linked, and we hope that these practises for ensuring a healthy work atmosphere can assist you and your coworkers in being both safe and efficient.

Conclusion

You've got it now. That is a list of ten tools that we believe everyone should consider whether they are a metal worker, own a store, or just have a strong hobby and want to learn metalworking. Some of the tools mentioned are more wants than needs, but most of the time, it is up to a professional metal fabricator to decide which tool is best for the job.